创新研发

随着多年的生产经验和创新的研发能力,Lienchy填充金属继续开发新功能或多样化的涂层钢铁产品,使涂层金属逐渐成为钢铁市场的不可或缺的表面处理金属产品。华体会桌面游戏肯定国内外客户。

- 相对于一般的金属表面处理,外膜可以美观或功能。

- 研发技术的重点是将不同的涂层或薄膜组合在金属表面,以保持良好的加工特性。

- 与金属材料新特性的开发相比,与不同用途或功能的材料相结合,开发成本和时间相对较快和经济。

- 随着材料技术的快速发展,涂层钢产品或预涂层钢产品的创新研发更加多样化,新产品的应用范围也更加广泛。华体会桌面游戏

创新的目的是满足客户前瞻性的需求。

Lienchy层压金属倾听客户的声音,致力于创造满足客户需求的层压产品。华体会桌面游戏利奇层压金属提供OEM/ODM定制服务,与客户共创蓝海市场。

-

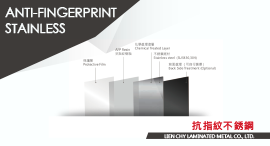

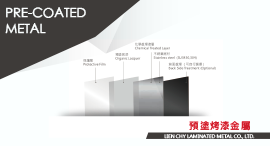

预涂

利奇层压金属可以为客户开发独特的用于预涂钢板的涂层。预涂钢,如防指纹不锈钢和部分涂层钢。什么是涂料,如何使用?涂层是涂层钢的基本材料之一。我们需要在钢卷或钢板上涂上涂料。然后将这些钢卷或钢板烘烤成预涂钢。有许多彩色涂料可以选择每涂层钢卷或钢板。应用于建筑、屋顶、车库卷帘门、冰箱、水塔、机器外箱、电器、车辆等。由于不同的应用有不同的规格,利奇复合金属开发了一种新的涂料,防指纹不锈钢系列。防指纹不锈钢系列具有耐油脂、疏水、6H硬度、易清洗等优点,非常适用于家用电器。对于一些机器部件可能需要部分涂层设计或开发的情况下。 The PVDF Laminated steel with good weather resistance that meet roof needs. Lienchy Laminated metal provid uniform coating technology is different from nomal low-cost pre-coated steel. The surface was per-coated over baking process still quite beautiful. There are many customers gived us many good evaluations.The custom coating of Lienchy Laminated Metal has the following advantages: 1. Lienchy Laminated Metal has more experience in research and development. We can help you reduce the cost of develop butget. 2. We protect your business secrets absolutely. To division of labor and cooperation, and create a win-win situation. 3. The unique formula and special coating technology can help you keep market competitiveness on your products. 4. Also we can do OEM production and never overlap their market. Our customers still retain their own brands. 5. Lienchy Laminated Metal has passed ISO 9001:2015 factory certification and meeted RoHS requirements. 6. Lienchy Laminated Metal has cooperated with many well-known companies. Ample supply with stable quality.Do you need a customized solution? Lienchy Laminated Metal can assist your needs to design and develop the coating with special specifications. However, we have a number of solutions for a variety of applications to solve your problems and save your time.Special recommendation: The Newest products of Lienchy Laminated Metal is "Anti-fingerprint(grease resistance) stainless steel", it has the following advantages: Oleophobic, non-yellowing, easy to clean, more resistant to wear, both aesthetic and practical.

-

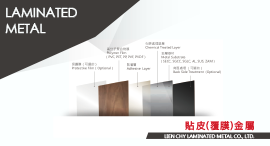

金属粘接技术(复合金属板)

Lienchy层压金属开发了一种卷对卷的金属粘接技术,可用于将不同的金属粘接成复合金属板,并开发了复合功能。Lienchy层压金属使用的是一种粘合技术,它使用一种自行开发的涂料,在烘烤过程后将两种金属粘合在一起。复合金属片将理想的性能和各种金属和合金的性能结合到材料中,从而使成品具有优越的质量和性能,如提高耐腐蚀性,降低孔隙率,比单个金属或合金质量更好。华体会桌面游戏成形性。复合金属板的优点:降低材料和制造成本,具有较低的孔隙率,较好的成形性,较好的工业设计灵活性,较好的导热性和导电性,较好的耐蚀性,较好的外观和耐磨性复合金属板可广泛应用于以下领域或行业:石油and gas chemical processing electrochemical structure system shipbuilding industry household appliance manufacturing air conditioning industry metal processing industry electronics industry

-

滚动卷预涂层技术

胶合技术的开发开始于4或5年前发展。在中东,那时的人们知道如何将沥青用作粘合剂。在埃及,大约3 500年前,有一个着名的犹太英雄,摩西。她的母亲,为了避开法老的大屠杀,把摩西放在沥青和沥青的糊状物中。在防水箱内,在尼罗河的岸边,结果由法老的公主节省,作为一个儿子采用,后来长大成为犹太救世主。在中国古代,使用粘合剂制成的动物皮喇叭,还有许多出土的遗物发现的胶水。到20世纪初,所用的大部分粘合剂都是皮革胶,骨胶,淀粉胶水和树脂胶水等天然产品.Today的工业产品尚未用于传统的天然粘合剂。华体会桌面游戏随着工业时代的出现,已经开发了各种粘合技术。Lienchy夹层金属开发了自己的卷起粘附技术,积累了经验和技术突破。胶合技术使用各种不同的原理来结合两种不同的物理性质。 When a PVC film, a PET film, and a PP film are combined in different metal substrates, adhesion techniques of different properties are utilized.Basic elements of gluing technologyAdhesion: Adhesion is the force or binding force of the adhesive and the adherend at the interface. The wetting of the adhesive by the adhesive is only a prerequisite for gluing. Adhesion must be formed to achieve the purpose of gluing. These include mechanical bonding, molecular forces, and chemical bonding forces.The theoretical basis of various gluing techniquesMechanical bonding theory: It is believed that the surface of the adherend has a certain roughness, and some surfaces are porous. The adhesive penetrates into the grooves or pores on the surface of the adherend, and is solidified like a small hook, nail, and root. The mucus forms a mechanical bond.Adsorption theory: It is believed that the adhesive force is generated by the mutual adsorption of the binder and the adherend molecules on the interface layer. This adsorption force is caused by the intermolecular interaction and belongs to the physical adsorption force.Chemical bond theory: It is believed that the adhesive reacts with the interface of the adherend to form a chemical bond, which is a high-strength bond.Diffusion theory: It is believed that the cement and the adherend molecules diffuse between each other, so that the interface gradually disappears, interweaving and firmly bonding. This theory is more suitable for polymer materials in which the adherend can be dissolved by the binder. This theory is still controversial for the bonding between metals.Electrostatic theory: It is believed that the interface between the adhesive and the adherend produces adhesion due to mutual attraction of static electricity.Advantages of roll-to-roll gluing technologyGood quality: In the gluing process, the stability of the adhesive is a key factor in the bonding force. Therefore, it is necessary to control the adhesive on the process. The roll-to-roll coating control is relatively easy, and it is baked in a crawler oven. The adhesion is stable and evenly distributed, and peeling is not easy to occur. Fast production: Because of continuous production, the production efficiency is several times that of the single-chip laminating machine. Lienchy Laminated Metal can produce 5,000 metric tons of coated steel products a year.Low cost: Roll-to-roll coating reduces unnecessary waste of adhesive, and coating thickness and uniformity are good, improving production yield and efficiency, and reducing unnecessary losses.Based on the foundation of various adhesive technologies, Lienchy Laminated Metal is used flexibly in the development of special coatings and adhesives to develop roll-to-roll coating technology for metal, metal to metal and special functional coatings. Lienchy Laminated Metal's research on basic adhesive technology, from theory to practice, continues to create innovative and high-quality coated steel products.

文档下载

热产品华体会桌面游戏